The Medsintez Plant presented new drugs at INNOPROM – 2023

From July 10 to 13, the International Industrial Exhibition INNOPROM – 2023 was held in Ekaterinburg; the Medsintez Plant presented its products at the joint booth of the Ministry of Industry and Trade of the Russian Federation. As part of the main topic of the exhibition, “Sustainable Production: Strategies for Renewal,” the company demonstrated its readiness to launch Russia’s first production of recombinant drugs, which are currently produced in Russia only by the Medsintez Plant. This year, representatives of the Russian Government headed by Mikhail Mishustin, Prime Minister of the Russian Federation, and heads of foreign delegations visited the exhibition. The delegates got acquainted with the advanced developments of leading Russian enterprises.

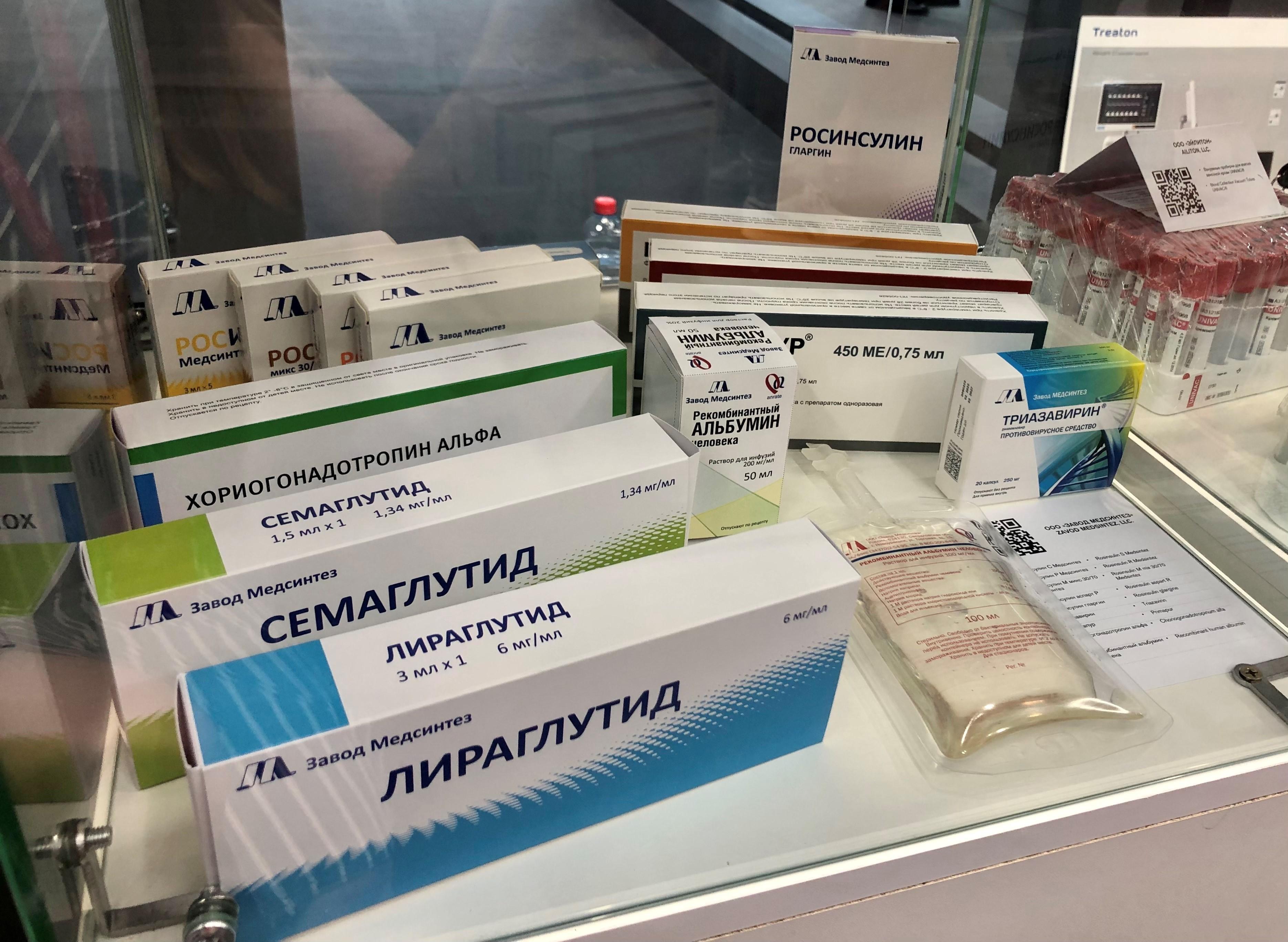

The Medsintez Plant is ready to launch a full-cycle production of drugs for treating type 2 diabetes mellitus – Liraglutide and Semaglutide. Today, own production of these drugs is necessary to ensure the country’s drug safety. Due to the departure of foreign manufacturers from Russia, these preparations were included in the list of out of stock drugs. The incidence of type 2 diabetes today accounts for 90% of the total number of patients. The drugs are produced in the most common dosage form – a disposable injection pen. The production capacity of the Medsintez Plant can meet 100% of Russia’s demand for these preparations.

Since 2018, the Medsintez Plant, in cooperation with IVFarma, has been producing the first Russian preparation of recombinant human follicle-stimulating hormone (FSH) for the treatment of infertility – Primapur. The Medsintez Plant developed and was the first in Russia to begin manufacturing the most convenient release form of FSH – disposable injection pens. FSG production capacity is 200-250% of the existing Russian market. The preparation is used in the IVF procedure and is included in the List of Vital and Essential Drugs. The modern Russian medicine needs a Russian-made FSH preparation to overcome reproductive problems of the population. Federal Law No. 323-FZ stipulates that citizens be provided with affordable infertility treatment using IVF procedure. Primapur is successfully used in clinics throughout Russia.

Addressing the issues of import substitution, the company develops other medicines for female reproductive health, such as the first Russian recombinant human chorionic gonadotropin (HCG). The preparation is used in the complex of assisted reproductive technologies (including IVF). Today, the Medsintez Plant has developed a substance and a finished dosage form of HCG, and preparations are underway for its preclinical studies. The preparation is necessary to create a full line of medicines for treating infertility, which will ensure drug safety in this area in Russia and allow not to depend on imported supplies.

The Medsintez Plant has developed a substance and a finished dosage form of recombinant human serum albumin, which is used to treat ascites in liver cirrhosis and blood loss. The development and application of the technology for producing this product is relevant and promising, since the preparation obtained by genetic engineering has the same biological activity as native human serum albumin, but unlike it, it has no impurities and can be produced on a large scale, free from pathogen contamination. The production of recombinant albumin does not depend on the number of donors, so there will be a demand for it (especially in the conditions of the special military operation) in Russia. The preparation has successfully passed preclinical studies; the application for a permission to conduct clinical trials has been submitted to the Ministry of Health of the Russian Federation.

Besides, the company presented its main products at the booth of the Ministry of Industry and Trade of the Russian Federation – human insulin Rosinsulin. Today, the Plant implements the full-cycle production of the whole product range of genetically engineered human insulin Rosinsulin and analogue human insulins Rosinsulin Aspart R and Rosinsulin Glargine made of own substances. The capacity of the finished dosage forms production area is up to 10 billion IU/year, and the production of substances is up to 200 kg/year, which makes it possible to meet up to 100% of the Russian market demand for insulin preparations. Rosinsulin preparations are produced in vials, cartridges and injection pens. The Medsintez Plant has developed and patented the design of disposable and reusable injection pens that ensure high precision dosing of the preparation. The production of insulin from own substance allows to completely abandon purchases from foreign companies and offer a stable price for the finished preparation in comparison with imported analogues. In 2023, the Plant is preparing to release the first Russian insulins for veterinary use.

Since 2014, the Plant has organized full-cycle production of the antiviral preparation Triazavirin, developed by Russian scientists on the basis of the original molecule. The preparation is effective for treatment and prevention of viral diseases, has a wide range of direct antiviral activity against RNA viral infections such as influenza, ARVI, COVID-19, tick-borne encephalitis, etc. Triazavirin is included in the federal clinical recommendations Influenza in Adults and ARVI in Adults of the Ministry of Health of Russia as a direct antiviral preparation. During the real-life clinical practice, the preparation has been included in a number of methodological recommendations, protocols for treatment and prophylaxis of COVID-19 and ARVI, including the recommendations of the Russian Ministry of Defense on the treatment of COVID-19. In 2022, clinical studies of the efficacy and safety of the use of Triazavirin in children aged 12–17 years with a diagnosis of acute respiratory viral infections were successfully completed. Currently, an approval is expected for clinical trials in children of the next age group – from 6 to 11 years.

For over 20 years, the Medsintez Plant has been continuously working on the development and production of complex preparations to ensure the drug safety of our country. High-tech production ensures a high level of quality and safety of manufactured products. The Plant’s technological capacities, competencies in biotechnological processes, interaction with scientific institutions, as well as the ability to develop and produce own devices for administering injectable drugs opens up the horizons for the Medsintez Plant in developing new innovative medicines.